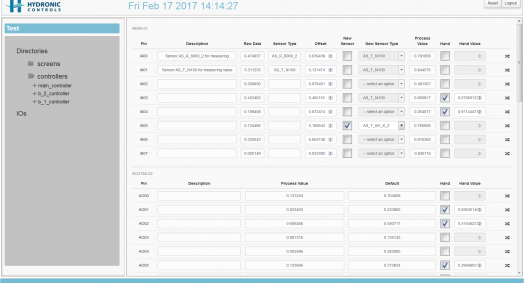

Direct on board programmed. No need for any special software on the PC, laptop or tablet. An Ethernet connection wired or wireless, established between the PC and the controller and any browser running on the PC, is enough to get in the controller and to program or modify any running parameter. Communication via Ethernet using HTTP/POST and GET requests.

Easy to upgrade via Ethernet. So life time support is available.

The whole project is based upon an RTOS, so that concurrent multitasking is supported for the micro-python algorithms.

The controller comes with a fixed accessing IP address, which can always be changed by the programmer.

A user friendly, short and yet powerful graphical interface guides the programmer and the user to hand the controller fast and efficiently. A well organized help and annotation system keeps the programmer up to date and well informed. A non expert on PLC, can easily handle the controller, program it and use all its capabilities in a very short time.

The microcontroller contains a small database written in json format for the ease of exchanging data, keeping a small memory footprint. The storage, which user can use is up to 55 MB for both micro-python algorithms and data.

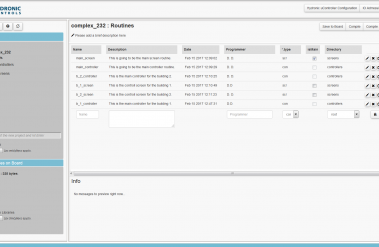

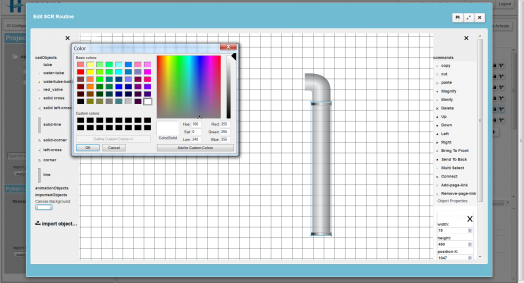

A completed running structure is a Project. Each controller can have in-stored many projects but can execute only one. Every project consists of routines. The routines can be such of python code (*.con) and such of screen graphics (*.scr). The con and scr routines communicate between them with the global variables, which are variables declared as such, in every routine.

The scr routines can appear in two formats, as stand alone, which means that the scr graphics are extended on the whole screen and as scr under a con, which means that the scr graphics appear as a modal in the screen. The number of the con, scr (stand alone) and scr/con (under a con) are limited only by the controller memory.

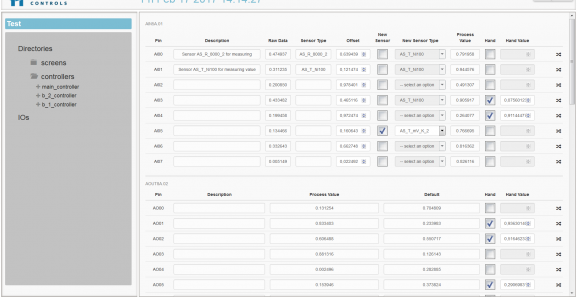

All IOs are faced as “routines without code” and with all their variables as global determined. So, the communication with the hardware is an easy and simple procedure.

A “library” is a normal project that consists of con and scr routines, doing a particular activity, like checking a boiler, a chiller, a pump etc. A “library” can be external imported to the controller and stored in. With the same way, a python library, a graphic object or a pdf file can be also imported. A project can be also exported from the controller to a PC, laptop or tablet.

A free projects library is offered through the engineering site, which is being extended with new projects all the time.

An optimized version of micro-python is the main language used for programming. Using micro-python and the Cortex-M CMSIS libraries, users can actually take advantage of assembly commands as well.

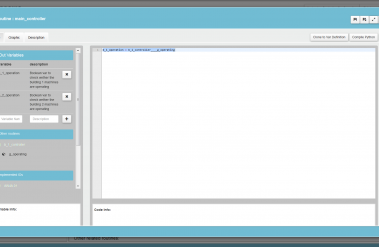

Every con routine provides a Python editor, where Python code can be freely written. If a Python library is uploaded, all its functions can be normally used. During code writing, a list of all global variables provided by all routines, are appearing on the left and can be easily downloaded and used in the code. Every variable from code needed, can be characterized as global and will be automatically transferred in the global variable list. The length of the code is only limited by the controller memory. An error-free compilation of the entire code of all con routines is required before activating a project.

Although all Python capabilities and functions are maintained, the feature of the code to act directly with the hardware is disabled. This is taken place only through the global variable structure system, between the routines and the IOs.

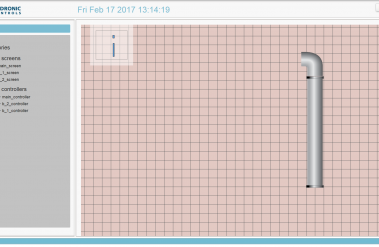

A user friendly and powerful graphic editor for developing scr routines is provided. Many embedded graphic objects are offered, by which the programmer can easily and effective create communication environment with the user and transfer Inputs and Outputs to the con and scr routines. Actually, there are no limits on the capabilities of designing and organizing a completed, good looking graphic presentation.

More individual graphic objects can be imported, handled and presented in the scr routines.

A controller can support up to 64 IO modules.

A permanent mapping between the S/N of the chip of each IO module and a number (1-64) for each IO module, given by the programmer, will be by “Auto Addressing” procedure determined. After that, by the installation, the controller is able to know in every case, where exactly every IO module is installed.

The mapping can be expanded by adding a new IO module, or downsized by unmounts an IO module. The mapping can be also canceled if needed.

For more information, please contact us: info@hydronic.gr